The Loren Group, has been manufacturing and supplying tapered steel friction piles (TSFPs) for deep foundation projects across the eastern United Sates for almost 30 years. Testing on these piles has been done in the past, however much of this was collected two decades ago. To fill in this large gap, we joined forces with industry experts and public infrastructure personnel. Together we designed and executed an applied comparison of TSFPs and more conventional uniform pipe piles. This report summarizes the testing process key insights we gathered.

Our testing program was only made possible due to the participation of the following professionals and organizations:

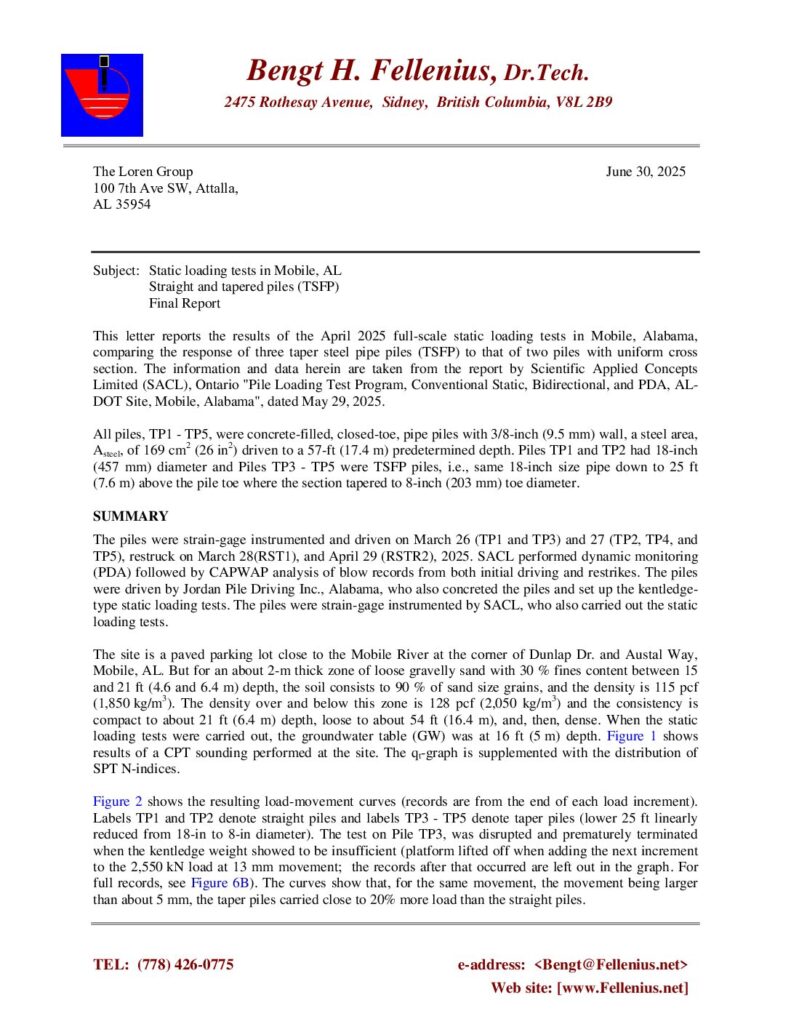

Dr. Bengt H. Fellenius – Designed the test program; a global leader in foundation design.

Sam Salem and his team from Scientific Applied Concepts LTD. (SACL) – Prepared the testing equipment and gathered the raw data.

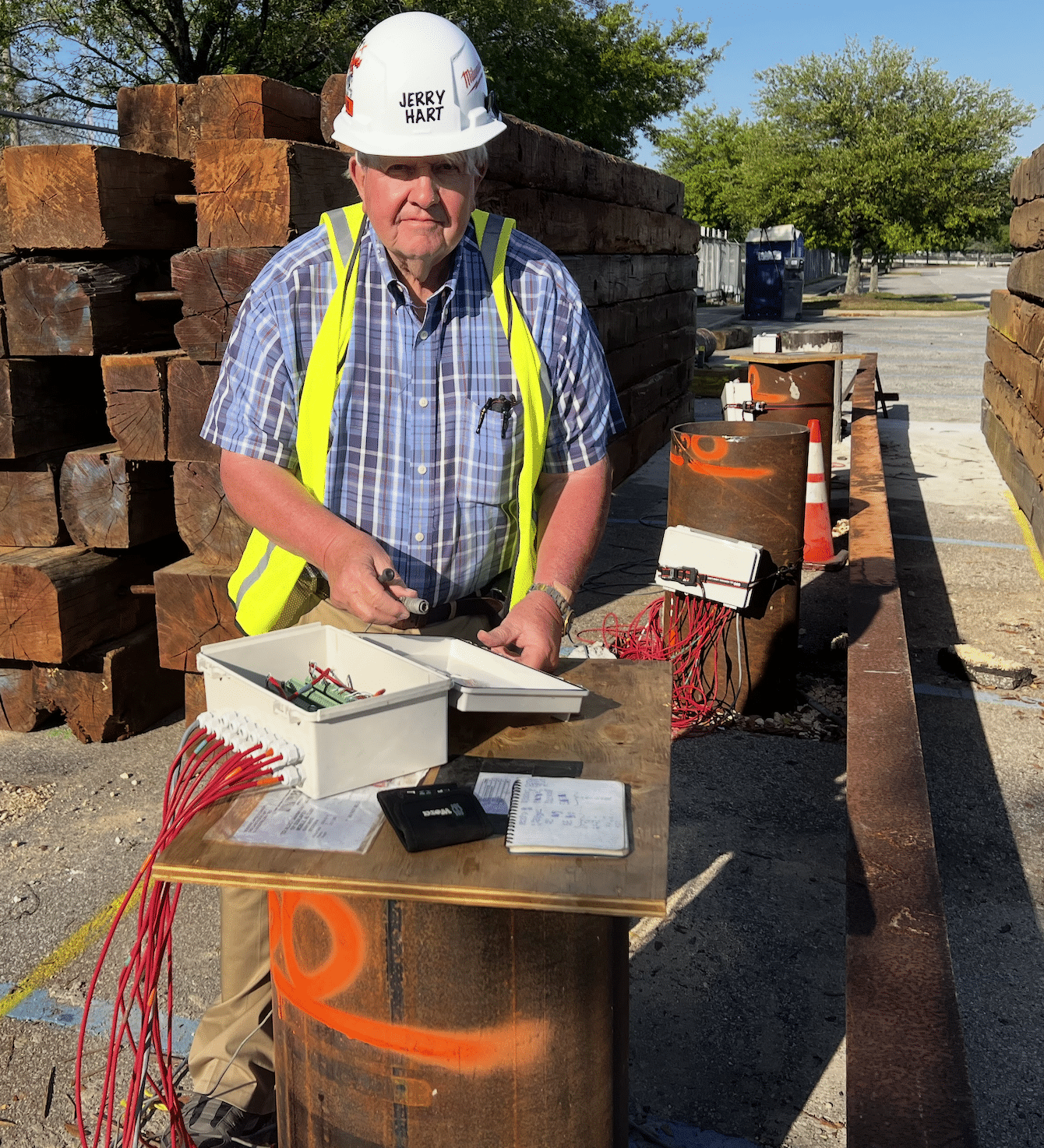

Jerry Hart – Coordinated and oversaw testing program.

Curtis Johnson and Jordan Pile Driving – Performed pile installation.

Kaye Davis and Alabama DOT – Donated the test site and contributed technical review.

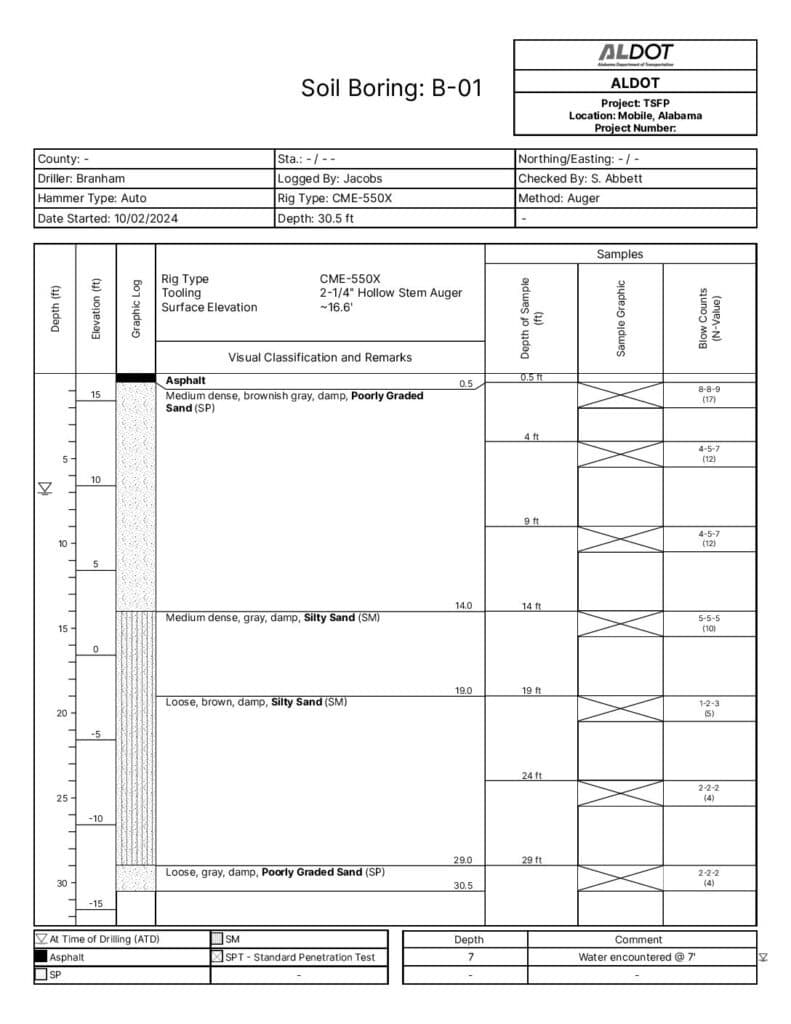

The Loren Group – Provided piling material.

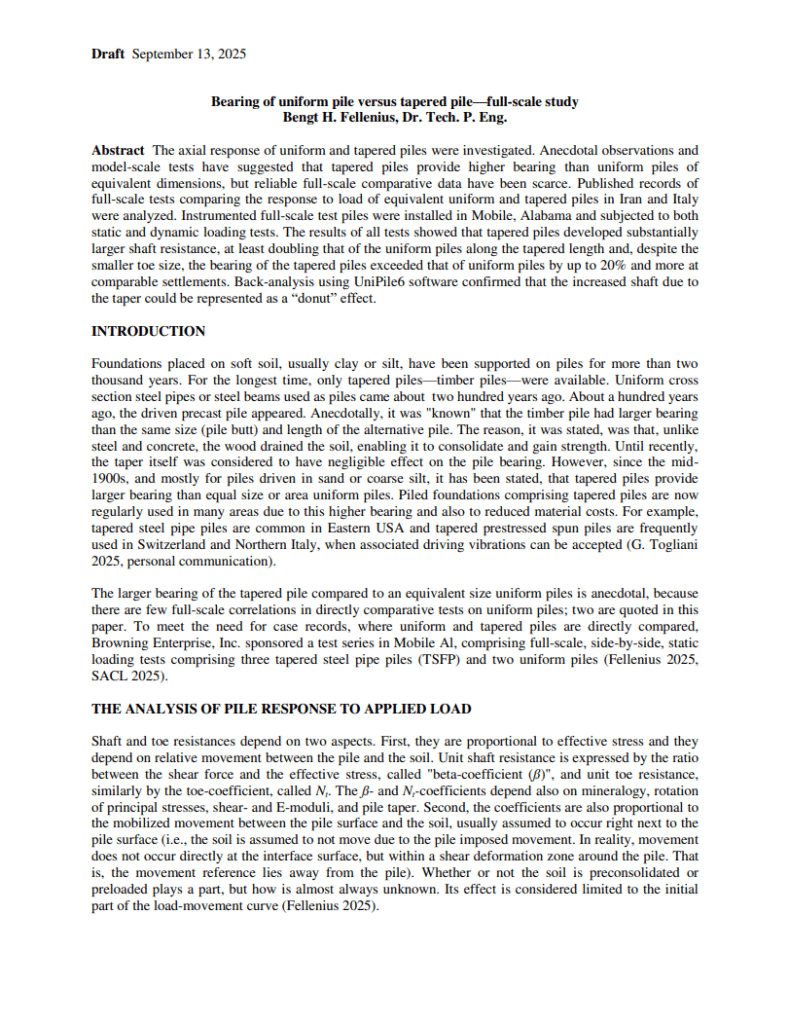

In Q1 of 2025 testing was conducted at a site located at Addsco Rd. and Dunlap Dr. in Mobile AL. This site, a small portion of a ~four-acre paved parking lot, provided by AL DOT, will one day be a part of a new bridge spanning the Mobile River. the soil at the site consists of 90 % of sand size grains, except for a ~six ft thick zone of soil with high fines content between 15 and 21 ft depth. The consistency of the sand is compact to about 21 ft depth, loose to about 54 ft, and then dense (sudden change at 54 ft depth). For more information on the testing location, please see and Test Program Report provided by SACL and the soil analysis provided by AL DOT.

A total of five piles were installed and tested: two straight side steel pipe piles and three steel tapered piles. Each pile was subjected pile driving analysis during the initial installation and two subsequent restrikes. Both static and dynamic load tests were conducted to evaluate the performance of each pile. For a detailed breakdown see the Test Program Report.

A total of five piles were installed and tested: two straight side steel pipe piles and three steel tapered piles. Each pile was subjected pile driving analysis during the initial installation and two subsequent restrikes. Both static and dynamic load tests were conducted to evaluate the performance of each pile. For a detailed breakdown see the Test Program Report.

The primary goals of this testing initiative were:

- Evaluate the real-world performance of TSFPs in soil conditions common in Alabama.

- Generate updated field data on to supplement experimental hypotheses and anecdotal evidence.

- Compare load capacity and installation behavior of TSFPs versus straight-sided pipe piles

- Determine if TSFPs offer advantages into a wider variety of soil conditions.

- Encourage innovation in deep foundation practices across the Southeastern US

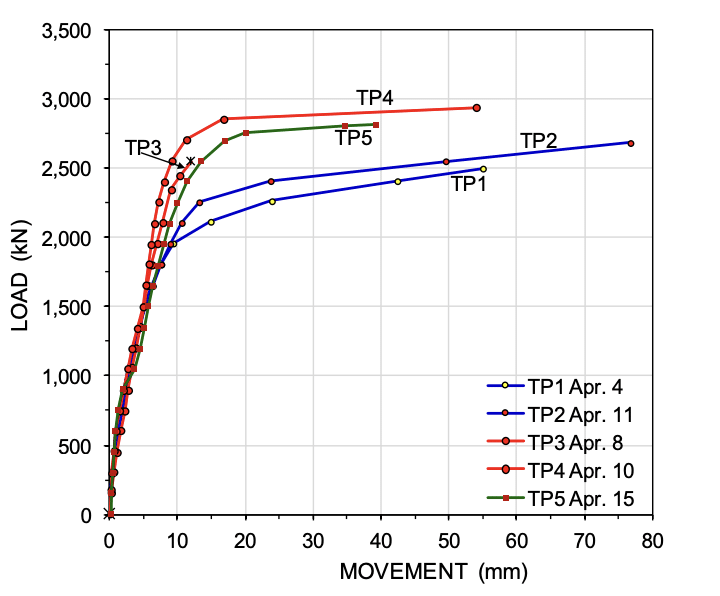

This testing initiative represents a significant advancement in deep foundation engineering. According to Dr. Fellenius, in this case the TSFPs demonstrated approximately a 20% increase in load capacity compared to the straight pipe pile at the same depth, and more at comparable settlements.

The Loren Group, has been manufacturing and supplying tapered steel friction piles (TSFPs) for deep foundation projects across the eastern United Sates for almost 30 years. Testing on these piles has been done in the past, however much of this was collected two decades ago. To fill in this large gap, we joined forces with industry experts and public infrastructure personnel. Together we designed and executed an applied comparison of TSFPs and more conventional uniform pipe piles. This report summarizes the testing process key insights we gathered.

Our testing program was only made possible due to the participation of the following professionals and organizations:

Dr. Bengt H. Fellenius – Designed the test program; a global leader in foundation design.

Sam Salem and his team from Scientific Applied Concepts LTD. (SACL) – Prepared the testing equipment and gathered the raw data.

Jerry Hart – Coordinated and oversaw testing program.

Curtis Johnson and Jordan Pile Driving – Performed pile installation.

Kaye Davis and Alabama DOT – Donated the test site and contributed technical review.

The Loren Group – Provided piling material.

In Q1 of 2025 testing was conducted at a site located at Addsco Rd. and Dunlap Dr. in Mobile AL. This site, a small portion of a ~four-acre paved parking lot, provided by AL DOT, will one day be a part of a new bridge spanning the Mobile River. the soil at the site consists of 90 % of sand size grains, except for a ~six ft thick zone of soil with high fines content between 15 and 21 ft depth. The consistency of the sand is compact to about 21 ft depth, loose to about 54 ft, and then dense (sudden change at 54 ft depth). For more information on the testing location, please see and Test Program Report provided by SACL and the soil analysis provided by AL DOT.

A total of five piles were installed and tested: two straight side steel pipe piles and three steel tapered piles. Each pile was subjected pile driving analysis during the initial installation and two subsequent restrikes. Both static and dynamic load tests were conducted to evaluate the performance of each pile. For a detailed breakdown see the Test Program Report.

The primary goals of this testing initiative were:

- Evaluate the real-world performance of TSFPs in soil conditions common in Alabama.

- Generate updated field data on to supplement experimental hypotheses and anecdotal evidence.

- Compare load capacity and installation behavior of TSFPs versus straight-sided pipe piles

- Determine if TSFPs offer advantages into a wider variety of soil conditions.

- Encourage innovation in deep foundation practices across the Southeastern US

This testing initiative represents a significant advancement in deep foundation engineering. According to Dr. Fellenius, in this case the TSFPs demonstrated approximately a 20% increase in load capacity compared to the straight pipe pile at the same depth, and more at comparable settlements.

In Q1 of 2025 testing was conducted at a site located at Addsco Rd. and Dunlap Dr. in Mobile AL. This site, a small portion of a ~four-acre paved parking lot, provided by AL DOT, will one day be a part of a new bridge spanning the Mobile River. the soil at the site consists of 90 % of sand size grains, except for a ~six ft thick zone of soil with high fines content between 15 and 21 ft depth. The consistency of the sand is compact to about 21 ft depth, loose to about 54 ft, and then dense (sudden change at 54 ft depth). For more information on the testing location, please see and Test Program Report provided by SACL and the soil analysis provided by AL DOT.

A total of five piles were installed and tested: two straight side steel pipe piles and three steel tapered piles. Each pile was subjected pile driving analysis during the initial installation and two subsequent restrikes. Both static and dynamic load tests were conducted to evaluate the performance of each pile. For a detailed breakdown see the Test Program Report.

The primary goals of this testing initiative were:

- Evaluate the real-world performance of TSFPs in soil conditions common in Alabama.

- Generate updated field data on to supplement experimental hypotheses and anecdotal evidence.

- Compare load capacity and installation behavior of TSFPs versus straight-sided pipe piles

- Determine if TSFPs offer advantages into a wider variety of soil conditions.

- Encourage innovation in deep foundation practices across the Southeastern US

This testing initiative represents a significant advancement in deep foundation engineering. According to Dr. Fellenius, in this case the TSFPs demonstrated approximately a 20% increase in load capacity compared to the straight pipe pile at the same depth, and more at comparable settlements.

This figure from Fellenius’ report, shows the load-movement curves of the piles, the taper piles carried close to 20% more load than the straight piles in this soil, and more at comparable settlements.

TP1 and TP2 are straight-sided pipe piles

TP3 – TP4 – TP5 are TSFP

These performance gains translate into practical benefits: Reduced pile length or fewer total piles, which in turn reduces the amount of steel pipe, rebar, concrete and driving time required. The cumulative effect is a measurable cost savings in material and labor. For more details, please refer to the Final Report provided by Dr. Fellenius as well as endorsements that we received after the testing program had been completed from the following participants: